THERMAL DISPERSANT COATING

Thermal dispersant rapidly disperses heat away from a coated component and evenly distributes heat over a coated surface. It aids in cooling heat sensitive parts and is excellent for superchargers , intercoolers , radiators , cylinder heads , intake manifolds, brake components, oil pans etc. It has very good chemical and corrosion resistance. Semi-gloss black in appearance.

Applications include:

- Superchargers

- Intercoolers

- Radiators

- Cylinder heads

- Intake manifolds

- Brake callipers and hats

- Oil pans

CERAMIC COATING

Ceramic-coating was initially developed for the aerospace industry and, like powdercoat, it found its way into the automotive industry. It’s essentially a high-solid paint product that’s concentrated with ceramic powder and provides a durable finish that reduces heat transfer when cured. It also inhibits corrosion and makes metals last longer, resists most stains, and is impervious to oil and fuel. In fact, very little sticks to it. Not only can it reduce underhood operating temperature and possibly improve performance, the fact that it requires little maintenance makes it ideal for any number of automotive uses. The coatings applied with Race Coatings will hold up to 800°C with polished finish and 1200°C with black finish. Very low maintenance and fantastic finish to the engine bay.

Applications include:

- Exhaust pipes

- Exhaust manifolds

- Turbo housings

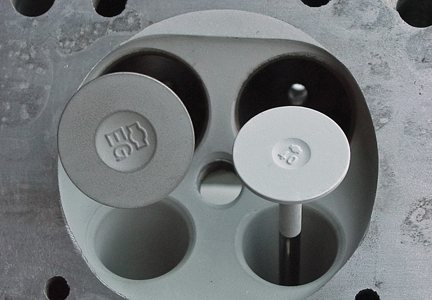

THERMAL BARRIER COATING

Thermal barrier coatings (TBC) are designed to prevent heat from penetrating and to reflect it back to its source. Our TBC is thermal shock resistant and survives cyclic heating and cooling and is protective to above 1,100°C

Keeps heat in combustion chamber longer through the power stroke, blurs hot spots, reduces the potential for detonation, increase torque and horsepower, Increase combustion chamber efficiency, reduced fuel consumption.

Applications include:

- Piston tops

- Combustion chambers

- Valve heads

DRY FILM LUBRICANT

Dry film lubricant coating is a high pressure, dry lubricant that reduces friction, galling and scuffing. It extends part life and requires no clearance changes to compensate for the coating. Apply to any part subject to sliding or rotating friction.

Applications include:

- Piston skirts

- Bearings

POWDER COATING

Powder coating is the electrostatic application of dry powder to metal surfaces which are then cured in an oven to 200°C to ensure a hardened, durable painted surface. Not only does this enable customers to enjoy the aesthetics of colour on a metal surface, the coating provides a hard finish which is tougher and more durable than conventional paint.

Applications include:

- K Frames

- Suspension components

- Brackets

- Wheels

- Tail Shafts

- Differential housings